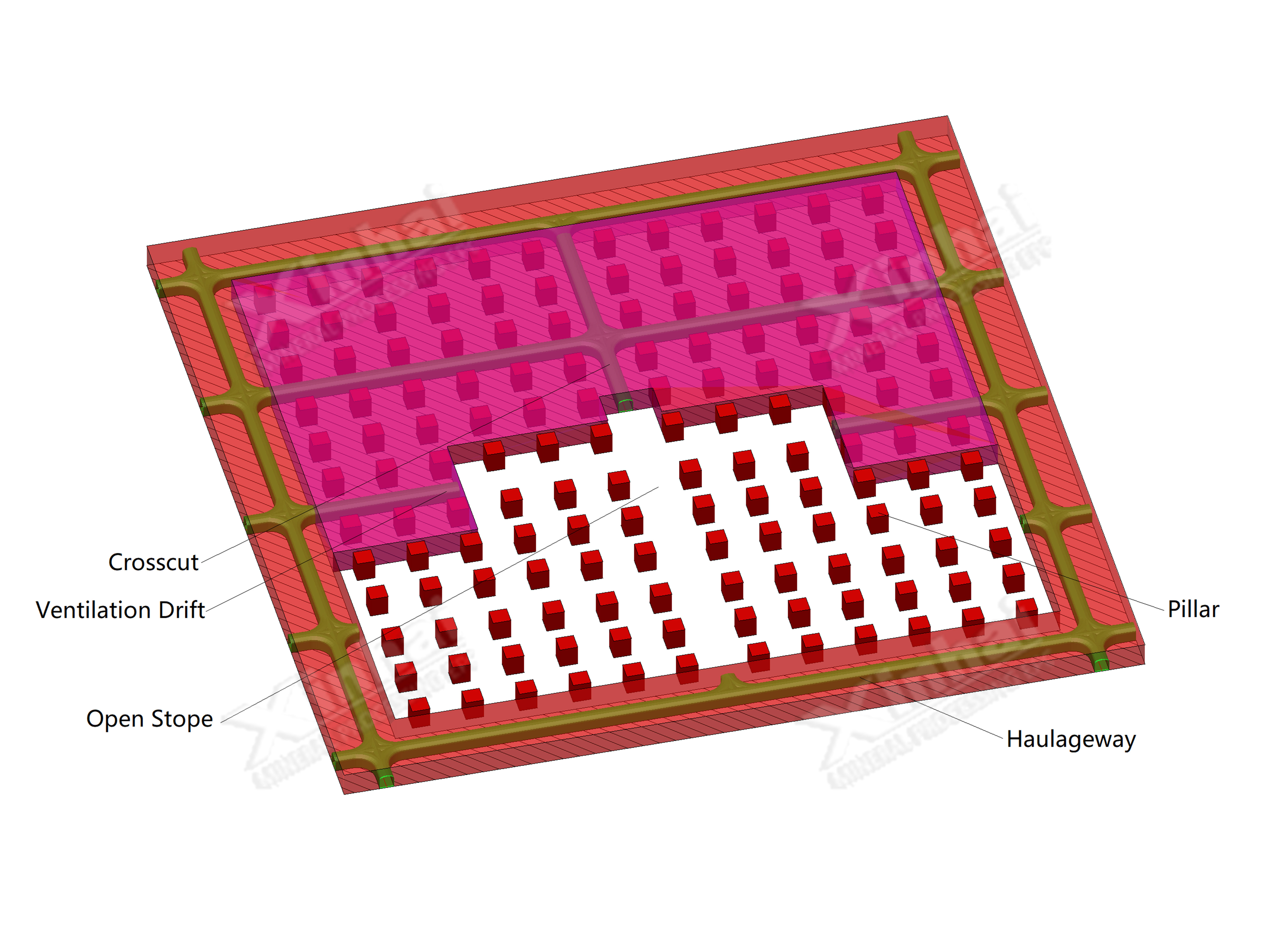

Room and Pillar Stoping

Post pillars are reserved in the stope for support. According to the depth of blasting holes, there are two mining methods: short-hole room and pillar stoping; medium- and deep-hole room and pillar stoping. The former adopts short-hole rock drill for orebodies with a thickness of less than 3-4m, and ore is transported by electric rake or scraper to the stope orepass. The latter adopts medium- and deep-hole rock drill for orebodies with a thickness of 5-30m, and ore is transported by scraper onto the dump truck.

TECHNOLOGY CHARACTERISTIC

It is usually applied in exploiting horizontal or slightly inclined, stable or moderately stable orebodies with a thickness of less than 30m.

Low costs, easy mechanization, and simple technology.

TECHNICAL INDEX

Stoping Method |

Production Capacity (t/d) |

Loss Rate (%) |

Dilution Rate (%) |

Room and pillar stoping |

100-250 |

15-20 |

8-10 |

MODE OF TRANSPORT

There are many transport methods, such as rail transport, trackless transport and belt conveyor. The specific method should be determined based on the orebody development scheme, transport volume and distance, mineral composition, ore properties, mining method and techno-economic comparison results.