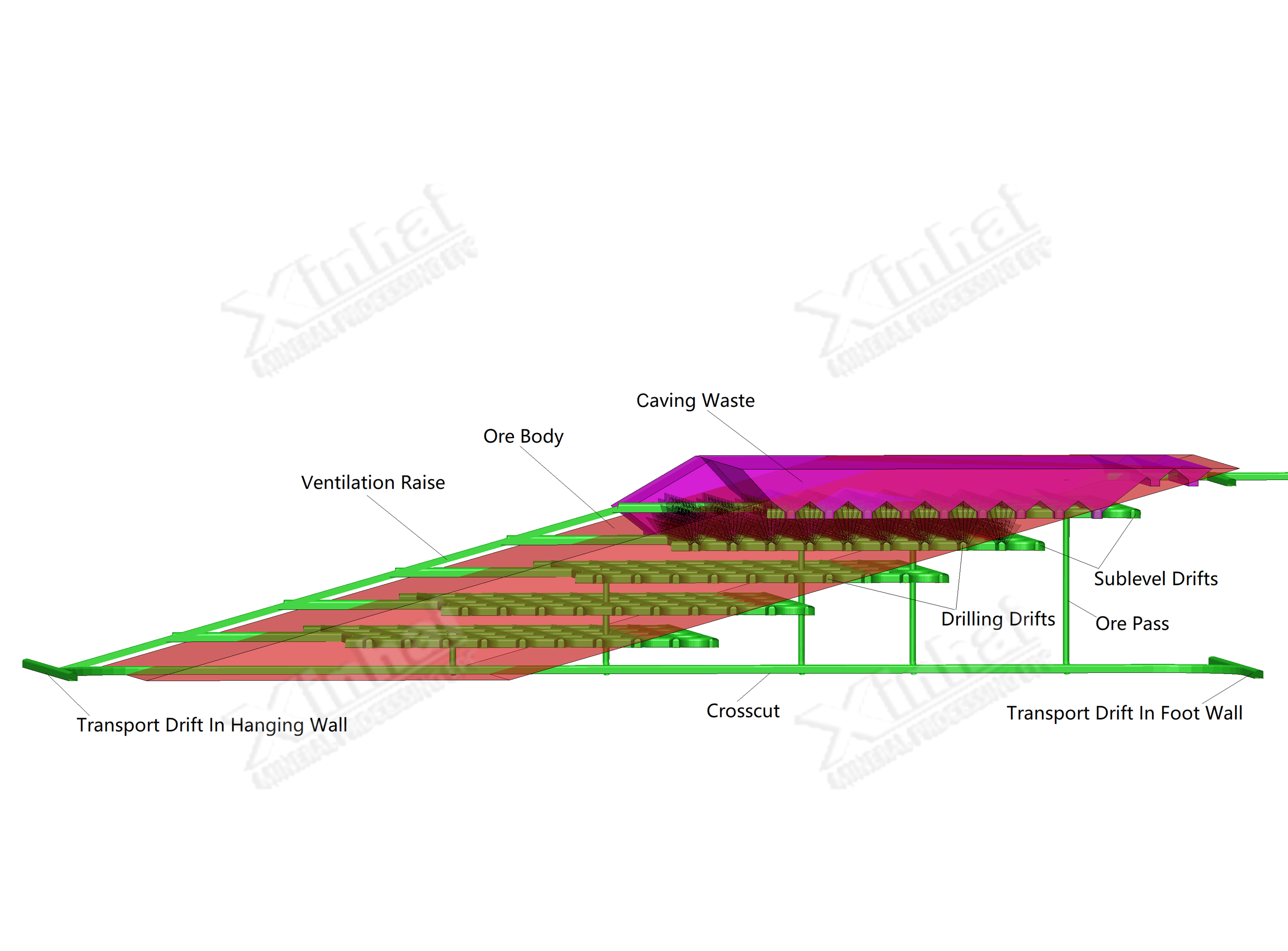

Sublevel Caving without Sill Pillar

Vertically, there are 3-5 sublevels in the stope room, with each measuring 12-15m in height. Medium- and deep-hole drill is adopted to drill upward fan-shaped holes in the drilling roadway. There should be overburden higher than the sublevel above the stoping face. When stoping is carried out in two sublevels, the upper sublevel should be exploited ahead of the lower one. Caved ore is discharged by scraper via sublevel roadway into orepass. After the completion of each sublevel, the orepass mouth should be sealed in time.

TECHNOLOGY CHARACTERISTIC

No caving impact on the ground, and orebodies without large water bodies and quicksand above;

Medium-level ore with lower grades and permission for certain loss and dilution;

Sharply inclined orebodies with thickness above the moderate level or slightly inclined, ultra-thick orebodies (ore has no agglomeration and spontaneous combustion);

Unstable or moderately stable hanging-wall rock, stable footwall surrounding rock, and stable or moderately stable orebodies.

Simple stope structure, high flexibility, and no need to reserve pillars;

Simple technology, and comprehensive mechanization through efficient automatic rock drilling, and loading and hauling equipment;

High degree of safety;

Large labor productivity and production capacity;

Higher recovery under large dilution rates.

TECHNICAL INDEX

Stoping Method |

Production Capacity (t/d) |

Loss Rate (%) |

Dilution Rate (%) |

Sublevel caving without sill pillar |

60-400 |

15-20 |

15-20 |

MODE OF TRANSPORT

There are many transport methods, such as rail transport, trackless transport and belt conveyor. The specific method should be determined based on the orebody development scheme, transport volume and distance, mineral composition, ore properties, mining method and techno-economic comparison results.